KOVOTIP, s.r.o. - LONG TERM TRADITION

MECHANICAL COMPANY DEALING WITH CHIP MACHINING OF STEEL, STAINLESS STEEL, NON-FRONOUS METALS AND PLASTIC.

The company KOVOTIP, s.r.o. is a family engineering company with a long tradition.

Our strengths are people, experience and precision. Our goal is customer satisfaction, reliability and achieving high quality of our products and services.

We are a dynamically developing company, where you will not only find a professional and confidential business partner, but above all the confidence of the entire team, which can fully realize your ideas and suggestions.

We mainly deal with the production of parts for all kinds of industries. The production program is focused on chip machining of ferrous and non-ferrous materials.

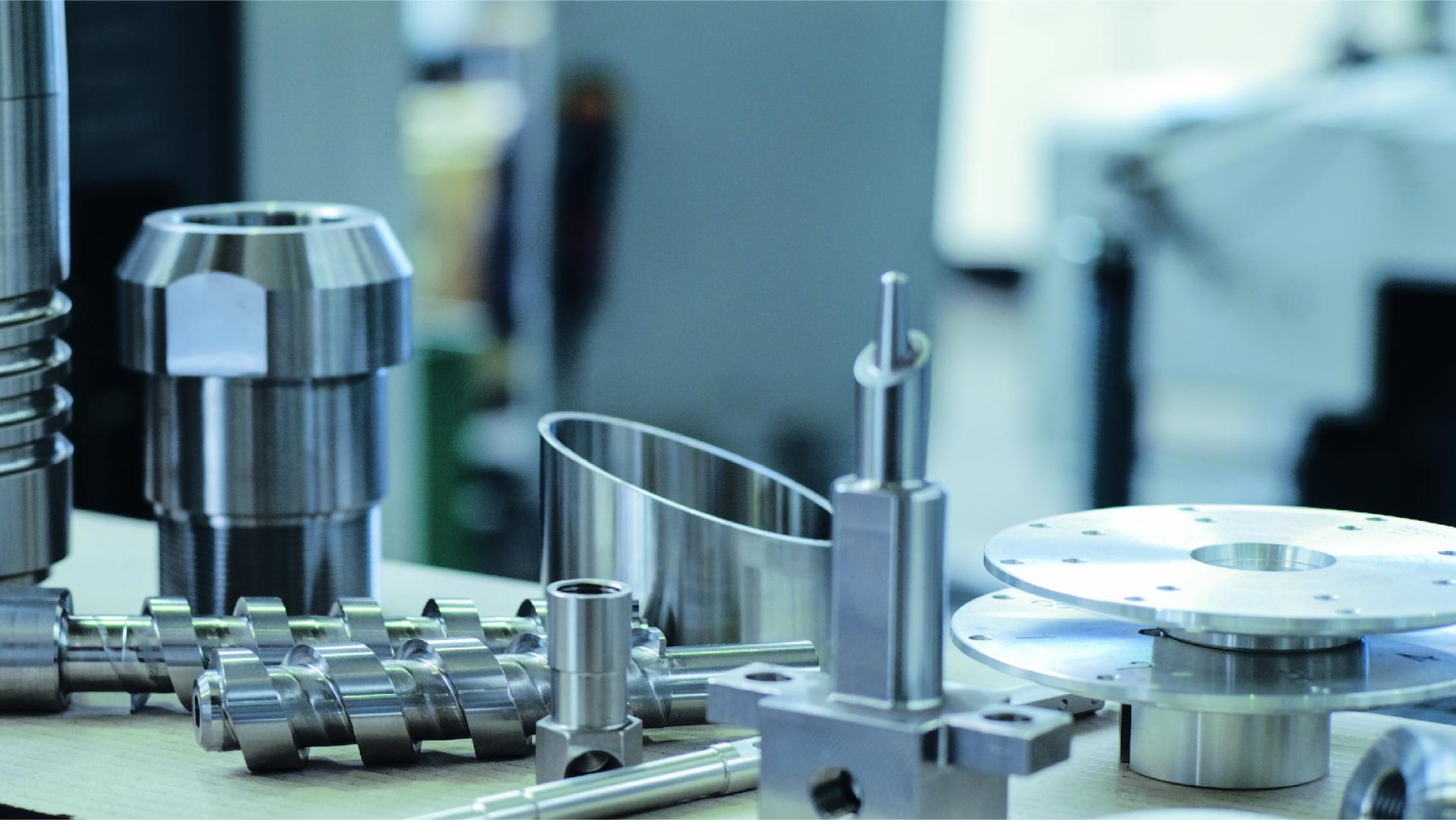

Different qualities of steel (11SMn30+C, S235, S355, C45, 42CrMo4, ...), brass, bronze, aluminum, stainless steel - stainless steel, copper, technical plastics (POM, PA6, PA66, PTFE+25% CARBON, ...) and other materials according to customer requirements.

We are trying to modernize the machine park and add to it him with a new generation of CNC machines.

We process the individual manufactured parts on CNC lathes, short-turn and long-turn curve (cam) automatic machines, but also on 6 and 8 spindle automatic lathes (AN and SAY). We also provide drilling, threading and material splitting.

We are machinery and equipment from small-scale production to large-scale production. The location, technologies and technical equipment of the company's production operations form a complete independent production cycle.

The manufactured parts are various pins, bushings, screws, nuts, adapters, hose connections, nipples, nipples, rings, couplings, reducers, axles, flanges and various other parts. Part of the manufacturing production is also assembled into finished products for the customer, where finished assemblies, product units and packages are assembled from parts.

For measurement, we use gauges of the leading MITUTOYO brand, threaded and cylindrical calipers.

In COOPERATION we can provide CNC bending, production of gears on a rolling mill, laser burning (also profiles), water jet cutting, surface treatments - RAL powder colors, galvanizing, anodizing, blackening and more. Also thermal surface treatments induction surface hardening, chrome plating, nitriding, - cementation.

If you are interested in our offer, do not hesitate to contact us.

Establishment of the company

Number of parts produced

Countries in which we purchase material

Professional services